PROBLEM

The vast majority of our built world is made up of virgin materials, many of them from finite resources, like fossil fuels. The construction industry is responsible for more than 30% of global greenhouse gas emissions. Of those emissions, a large amount is caused by the extraction and refinement of raw materials. In the UK alone, one ton goes to waste for every four tons of building material used. BAUX, a co-founded venture from FUWL, tapped the Swedish textile industry to transform what was destined for landfill into an upcycled innovation.

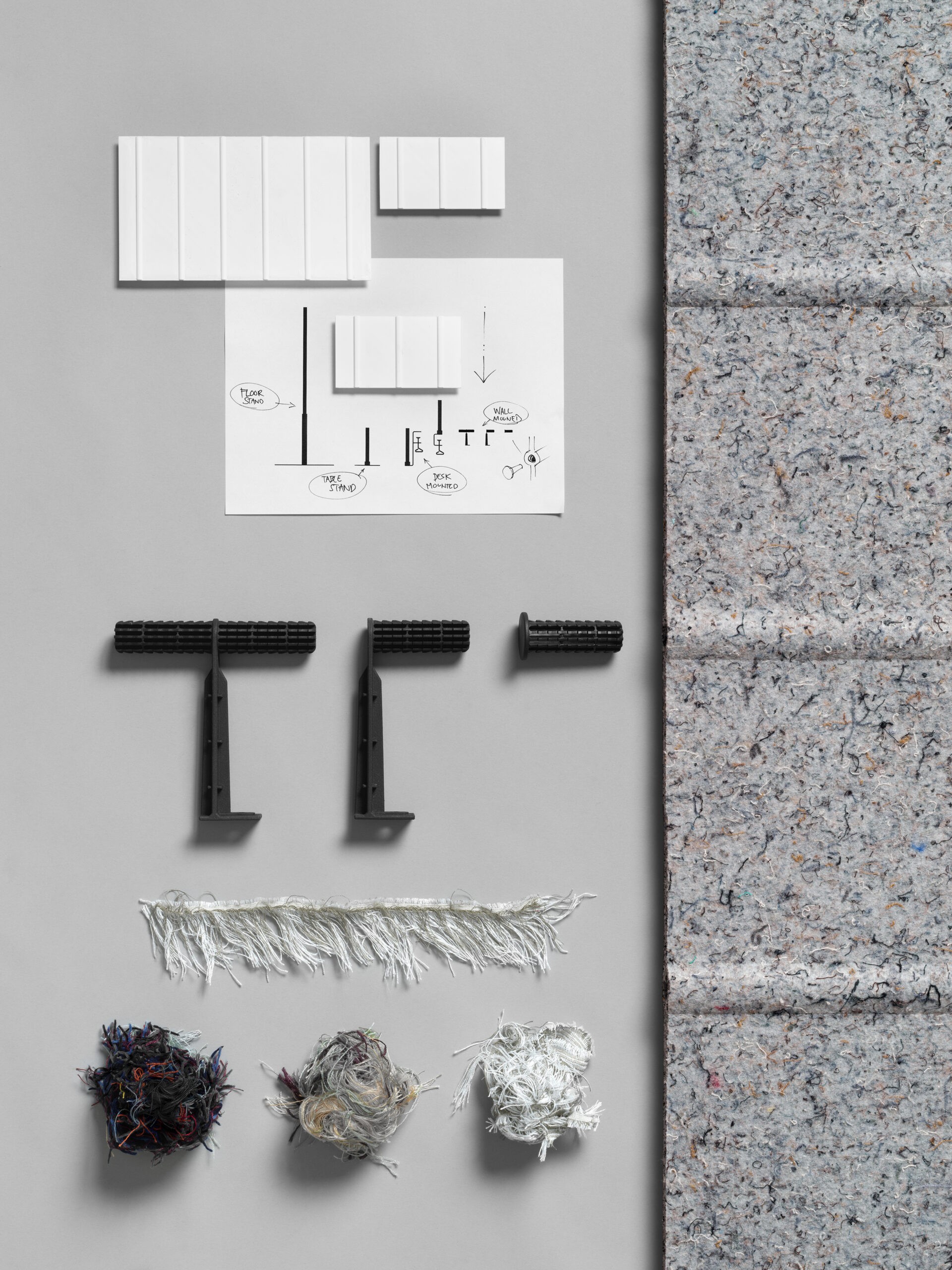

PROCESS

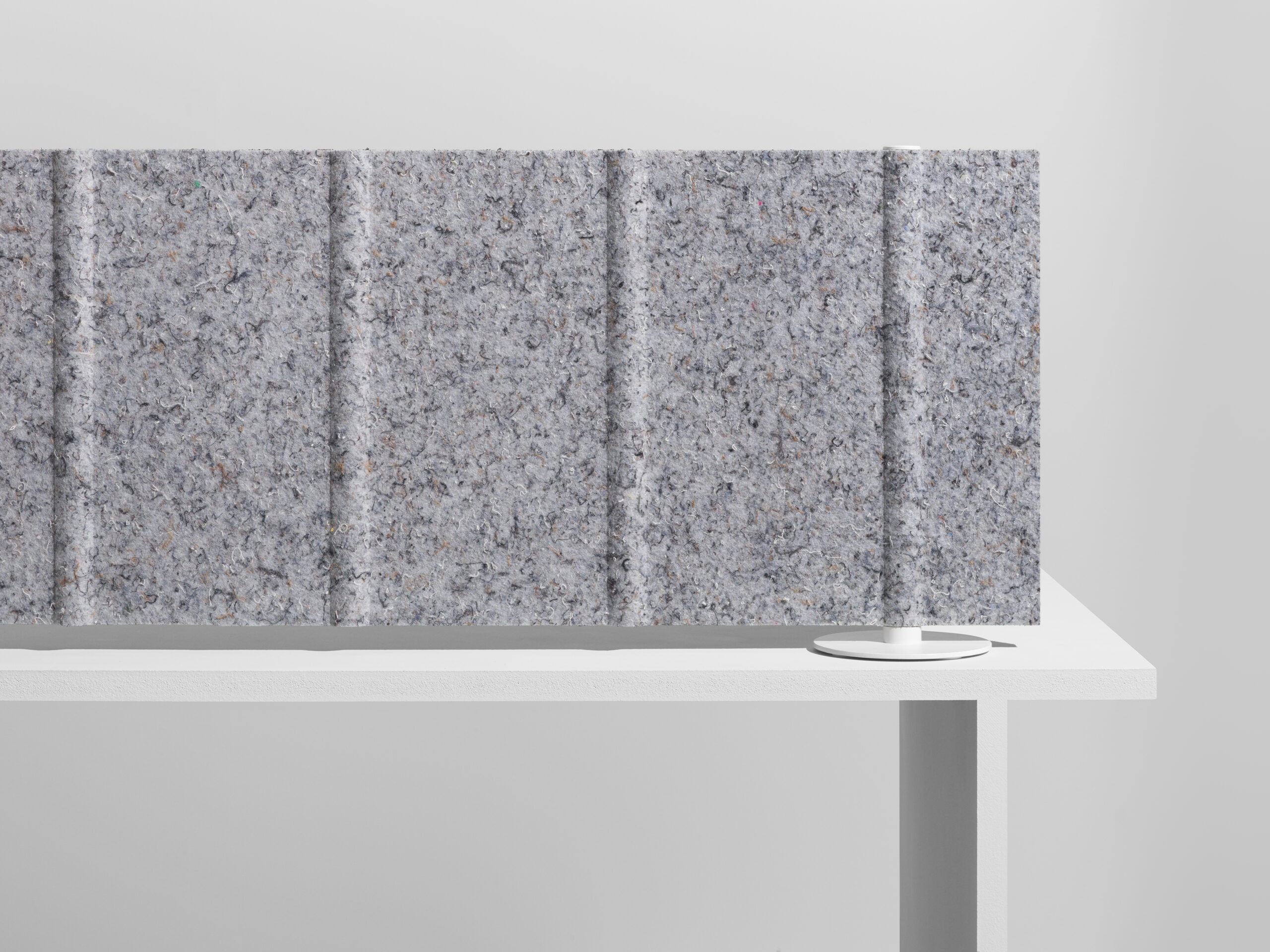

Partnering with the renowned The Loop Factory and the well-established textile producer Ludvig Svensson, the team began the design process to turn textile offcuts into acoustics. The idea is to save resources by using already manufactured materials and re-applying them to new products. The resulting acoustic material is created by combining 100% polyester based threads with energy-efficient polyester fibre. The manufacturing process is so efficient that the final product produces no waste of its own in manufacturing, thanks to how it was designed to accept all the offcut fibre qualities.

SOLUTION

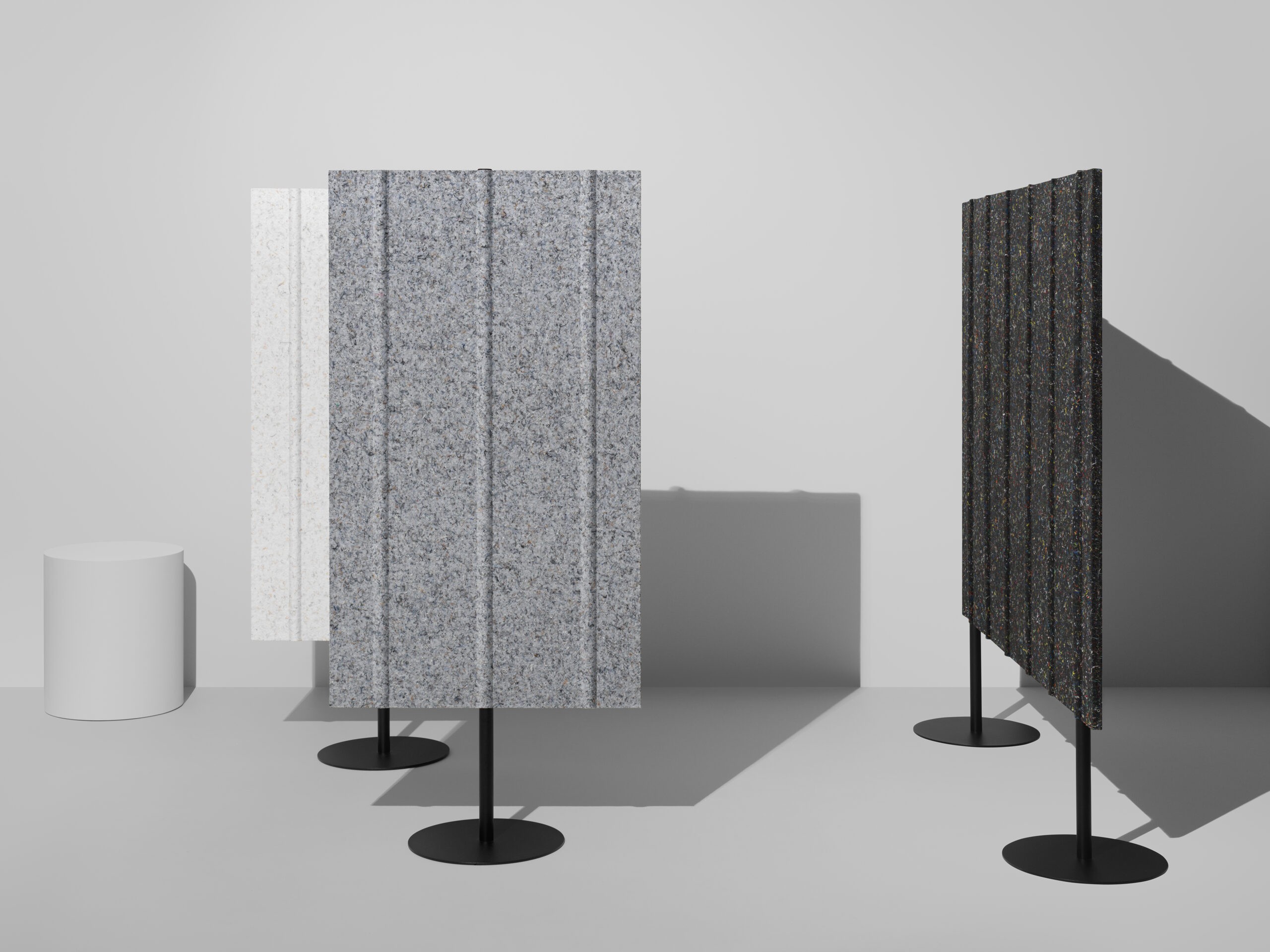

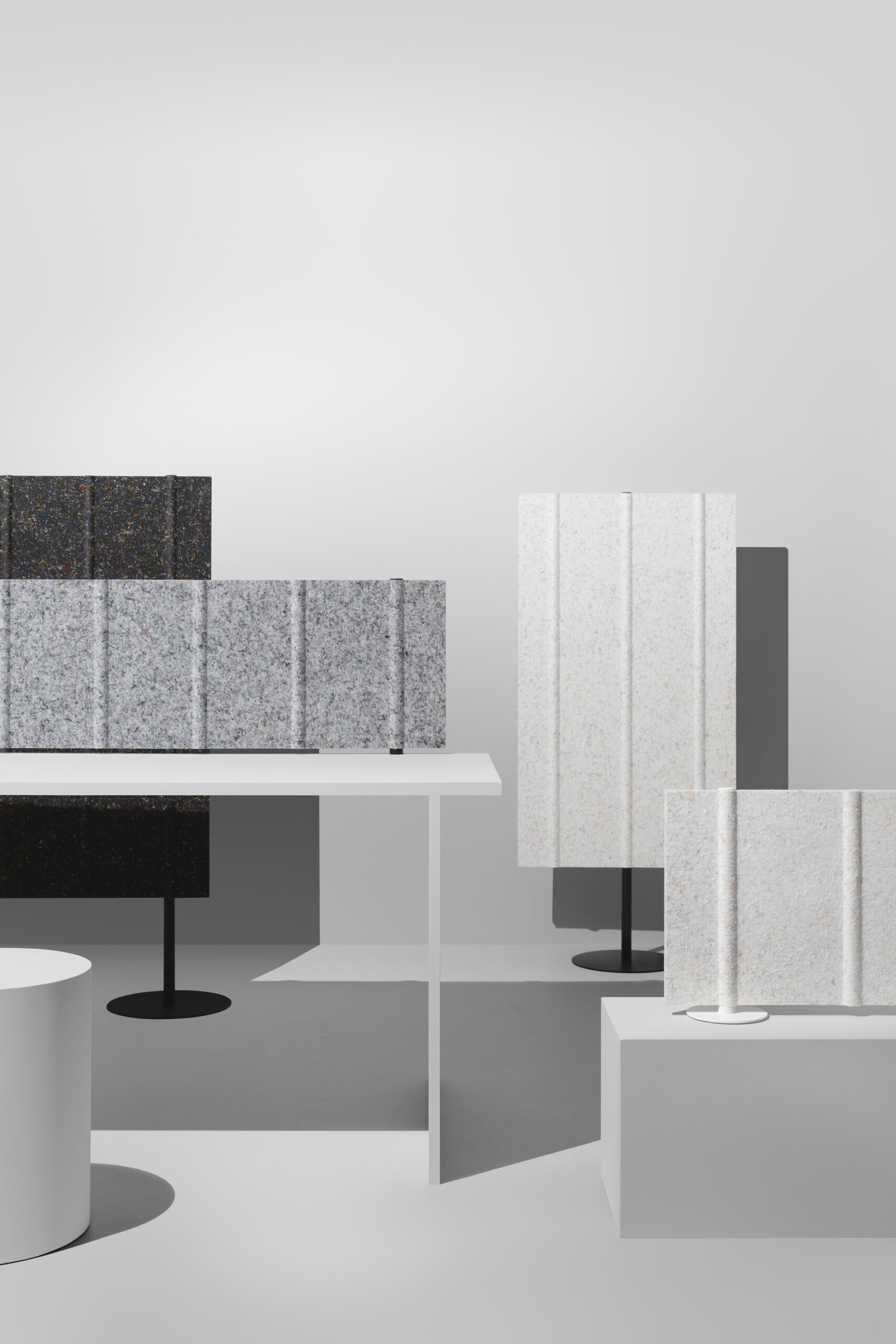

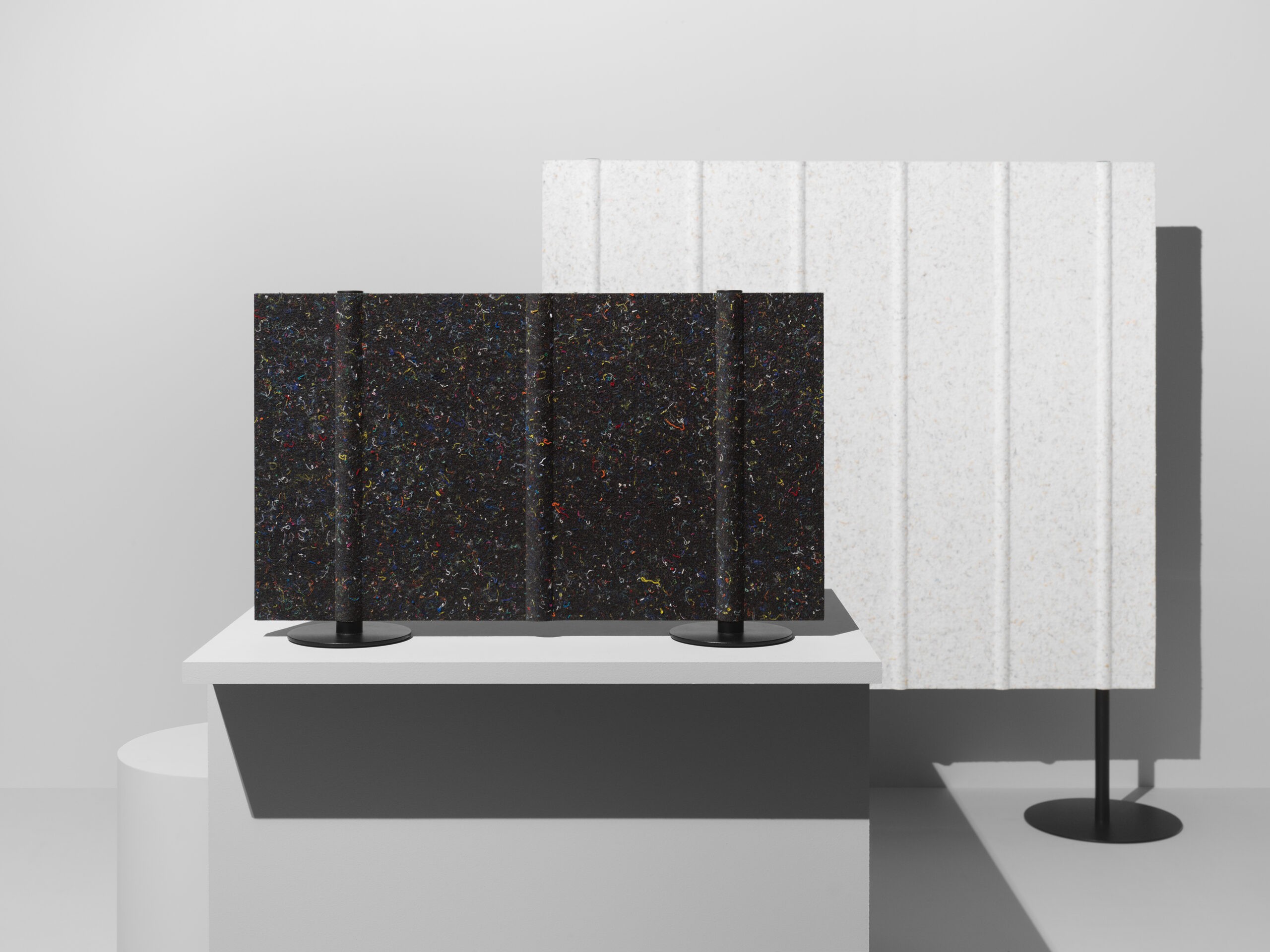

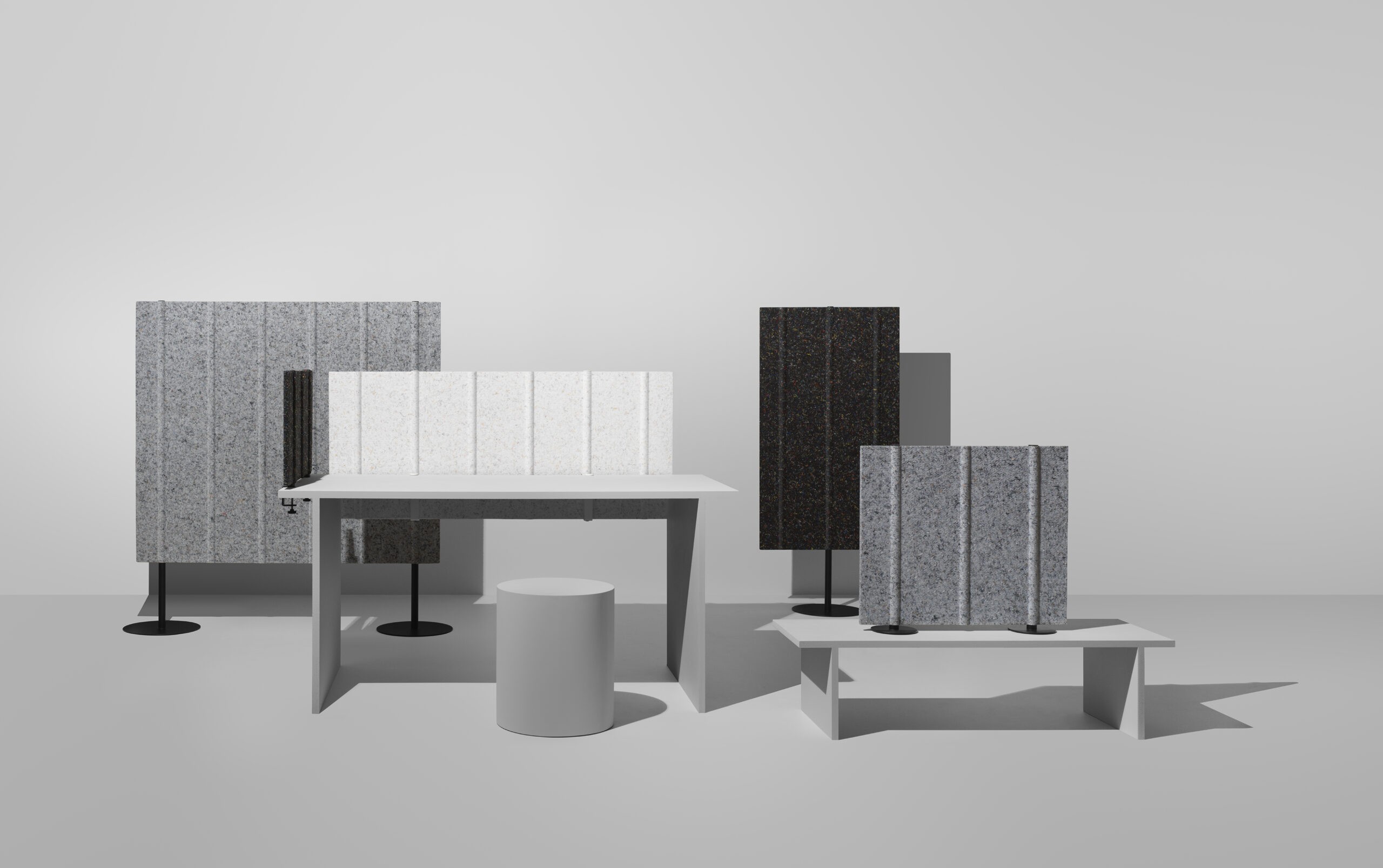

BAUX Acoustic Felt is designed to enhance acoustics and make partitions within the workplace without the need for heavy construction. The felt system puts to good use the upcycled fibers without compromising on the performance we all expect.

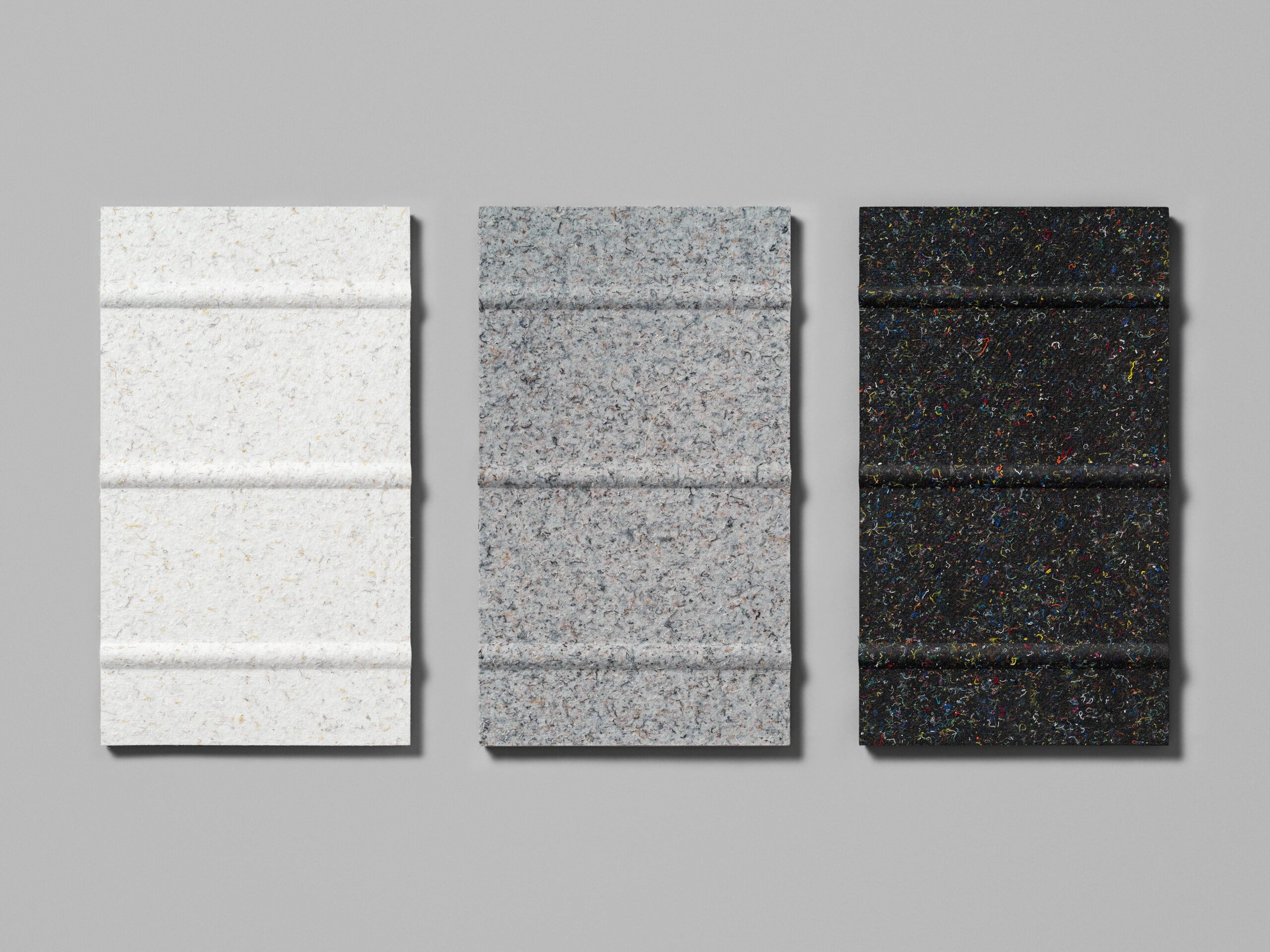

BAUX Acoustic Felt comes in hues of industrial offcuts, from light to dark, and with a subtle melange of colorful threads that naturally result from repurposing waste fibers. It’s completely scalable from a clamped desk divider to a free-standing partition. The design applications within the workplace are as of yet to be fully explored.