Prototypa #29 Stilride

Effortlessly reinventing steel manufacturing

Since adolescence, the two friends, engineer Tue Beijer and entrepreneur Jonas Nyvang had ‘investors breakfasts’ together to come up with new systems that would change the world. They were seduced by the idea of prototyping their way to more economic manufacturing of steel, which led to Stilride, a brand they co-founded in 2020. Over thirty prototypes were featured at the large table at Form Us With Love’s studio accompanied by a motorbike for the 29th issue of Prototypa in June, a forum that aims to explore how we take better decisions through iteration.

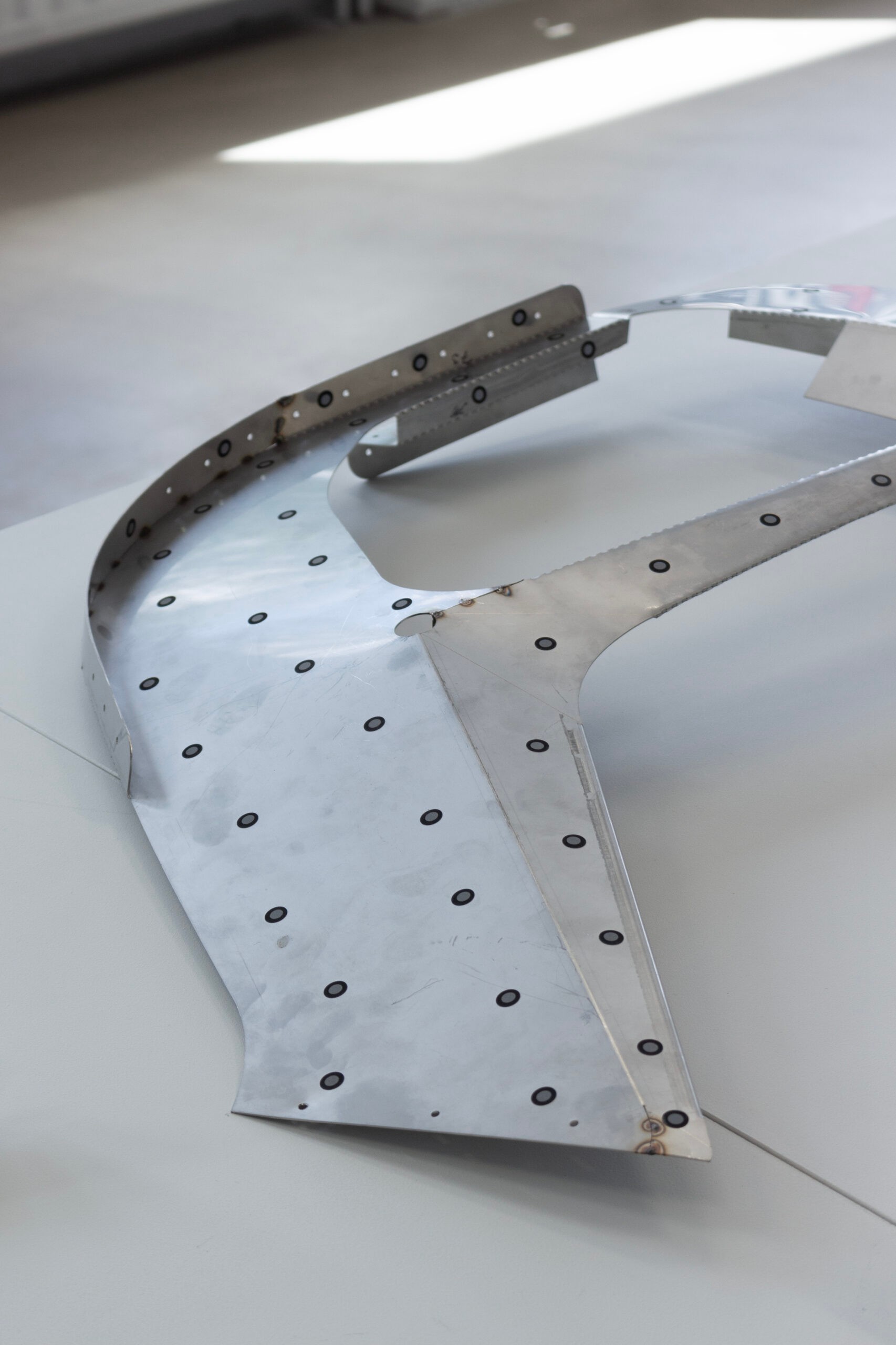

The prototypes were made from both paper and steel: and we immediately began the session with the relationship between the two materials and how one informs the other, unpacking infinite possibilities that come with starting to prototype in paper and then applying it to steel. “We try to experiment with the whole value chain, by engineering our own software we can go from paper to patterns, to folding metal, which enables us to prototype from the beginning to the end,” Beijer explains.

What do we learn from this type of iterating? Perhaps it is all about having something to communicate with, in this case, a bigger ambition is simplified through an electric scooter, a full-scale prototype on display at the session. “In the case of Stilride, the motorbike is our Trojan horse to communicate our folding technique,” says Beijer, you can invent a cool software, but if you are not able to get something out of it, it’s not worth anything” he continues. “We spoke to Mercedes a couple of weeks ago about a potential collaboration and could never have had that conversation without being able to show anything real.”

During the last three years, the challenge at Stilride has been all about how much can you reduce. And as Beijer points out, it’s all in the folds. Speaking at the Prototypa session is also Design Manager, Ricardo Sá Freire “I am more in love with the process than with the product,” he says. “Design optimisation in folds is very much being a mathematician. We start with a sheet of paper and shapes you want to cut, then you begin to find the tessellation between them. Knowing we could solve it, using zero waste: we push for new angles, springs, and robotics — but it’s all maths in the end.”

Fail fast is another approach dear to the brand. This is constantly present in Stilride’s work. “Earlier today, we did 60 different tests on the same curve at different speeds and angles, the quicker the insight the better,” Sá Freire shares.

One of the brand’s key visions is to reinvent a system that could scale globally, just like Tetra Pak did in the 80s. And why not? It seems almost too easy: Stilride shipping code to any workshops that handle sheet metal in the world, democratising where an electric vehicle can be made. It sounds revolutionary and possible, but how do we best iterate this new supply chain? “You must find the end of the yarn and start to unwind,” Beijer says “Avoiding doing everything at once. We started with an idea, doing something with sheets, and then proving it through something people can relate to, like a scooter and then you can talk about all the other things. You don’t want to lay it all out, and become the crazy inventor, that no one will hear,” says Beijer.

Stilride is a great example of a growing tendency for Swedish designers to become manufacturers, creating a dual role. It seems, partly an environmental and economic decision, but also about proving you can do it. “The beauty of the design is when you scrutinise it. A standard scooter has a hundred fifty parts, ours have eight,” Sá Freire points out. “Standard components can easily go out of the market, and then you must redesign around it, dictated by the parts. We just do all of it ourselves,” Beijer states “You want to own the process,” he concludes.

Prototypa #29, ended with a beautiful participatory session, a master class in steel folds if you like. And we were all left thinking: this has every opportunity to scale, fast. The truth is, Beijer and Nyvang knew they sat on something special, however, it took them until mid-life, to find the right timing. But when they did, they went full force, iterating with great speed, confidence, and ease, developing not only green mobility in the form of a new e-motorbike but an entirely new way of manufacturing steel, all in the name of future efficiency and resilience.

— Text by Lia Forslund

About Prototypa

A platform for creative iteration. We live in a world where we have to make better decisions. The way these decisions are made is dependent on the ideas behind them, how the ideas are assessed, but also how they are communicated. Prototypa is a forum across industries for creative challenges, interesting provocations and honest voices in and around the act of prototyping. Guests leave with learnings, new curiosity, and straight answers to some, often, abstract questions.

About Stilride

A platform for creative iteration. We live in a world where we have to make better decisions. The way these decisions are made is dependent on the ideas behind them, how the ideas are assessed, but also how they are communicated. Prototypa is a forum across industries for creative challenges, interesting provocations and honest voices in and around the act of prototyping. Guests leave with learnings, new curiosity, and straight answers to some, often, abstract questions.